New video out now: Amiblu Storage and Retention Systems

Watch our new video: How Amiblu storage and retention systems help cities manage rainwater, reduce flooding, and boost climate resilience.

Amiblu Group obtains EcoVadis certification

Amiblu has successfully passed the 2024 EcoVadis audit and received the “Committed” badge for our sustainability management system.

Relaunch of the Amiblu Project Reference Database

Explore 30,000+ GRP projects in Amiblu’s new Reference Database with an interactive map, visual case studies, and improved usability.

#WeAreAmiblu – Interview with Anabel Benito Llatge

"At Amiblu, we never stop learning." - Interview with Anabel Benito Llatge, Human Resources Coordinator at Amiblu Pipes Spain

Amiblu Australia achieves triple ISO certification

Amiblu Australia has successfully achieved certification to ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health & Safety)!

Amiblu supports UNESCO World Engineering Day 2025 campaign

Amiblu is an official partner of UNESCO's World Engineering Day 2025 campaign, highlighting engineering's role in sustainable development and climate solutions.

Amitech Morocco obtains ISO 14001 certification

We are proud to announce that Amitech Morocco has obtained the ISO 14001 certification, confirming the company's strong commitment to environmental management and sustainable development.

Amiblu PROX: The Next Step in Sustainable Product Development

Amiblu PROX is an advanced sustainable pipe solution designed to significantly reduce CO2 emissions across water and energy infrastructure projects.

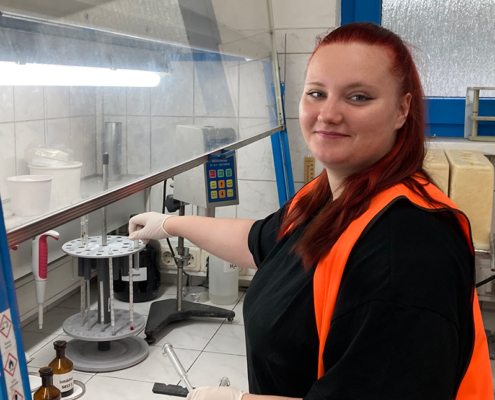

#WeAreAmiblu – Interview with Angelina Skopnik

"Amiblu was flexible with my application and helped me find the best fit, which turned out to be quality management and working with tests and chemicals."

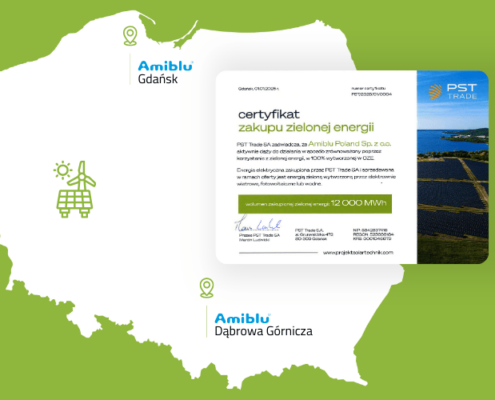

Amiblu Poland factories now 100% renewable-powered

As of 2025, Amiblu’s Polish factories run on 100% renewable energy, joining our CO2-neutral Spain plant in reaching key sustainability milestones.

Amiblu solution for rainwater overflow Schmölz

Only corrosion-resistant GRP components from Amiblu Germany GmbH are used in renovating the Schmölz I pumping station in Küps, Bavaria.

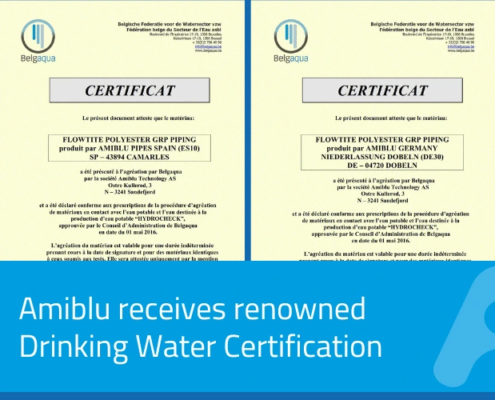

Amiblu receives renowned Drinking Water Certification

Amiblu receives prestigious BELGAQUA drinking water certification for Amiblu Flowtite GRP pressure pipes.

Interview with Angel Simon, Project Manager at Amiblu Pipes Spain

"Amiblu is a company that promotes professional and personal growth." - Interview with Angel Simon, Project Manager at Amiblu Pipes Spain

Amiblu partners up with the Swedish Life Cycle Center

Amiblu partners with the Swedish Life Cycle Center to drive sustainability, innovation, and provide transparent, high-quality life cycle data.

Amiblu Group appoints new CFO

A warm welcome to Regina Zorn! She brings 25 years of finance experience across industries such as packaging, electronics, and chemical manufacturing.

Interview with Rafael Lahera, Commercial Director Latin America

"We are constantly learning and facing new challenges." - Interview with Rafael Lahera, Commercial Director for Latin America at Amiblu Pipes Spain

Amiblu acquires RPC Pipe Systems Australia

We are pleased to announce that RPC Pipe Systems has been acquired by Amiblu, RPC’s technology partner for Flowtite pipe systems.

Successful accreditation renewal of the Amiblu Testing Laboratory in Norway

We're proud to announce that our laboratory has successfully passed its comprehensive accreditation renewal review by Norwegian Accreditation.

New video out now: Hobas Technology – the Centrifugal Casting Process

Amiblu pipes with Hobas technology are produced by centrifugal casting in a 100 % computer-controlled process. Watch the video and learn more!

World Environment Day 2024

This year's World Environment Day 2024 focuses on land restoration, desertification and drought resilience under the slogan “Our land. Our future. We are #GenerationRestoration."

Watch our new sustainability video!

Our new video highlights what sustainability means to us and showcases the innovative solutions we develop for food, safe water, clean environments, and green energy.

2-in-1 water management solution by Amiblu GRP

To connect an additional 30,000 inhabitants to the local water supply system, a 2-in-1 water management solution by Amiblu has been conducted in Zagreb, Croatia.

New GRP irrigation system for 12,000 ha in Cuneo, IT

The Bealera Maestra – Destra Stura Consortium upgrades irrigation system in Cuneo, Italy with Amiblu pressure pipes.

New brochure on Amiblu Industry Solutions out now!

Download our new brochure on Amiblu industry solutions and learn more about how our expertise can benefit your project.

Amiblu NC Line: The chameleons among pipe systems

Non-circular GRP profiles are the chameleons in the world of water infrastructure. We asked Alexis Capoul to tell us more about the functionality of these versatile products.

Amiblu relining pipes protect sewer network from H2S attacks

Amiblu relining pipes replace concrete pipes that were severely damaged due to H2S attack in Potters Way, Peterborough, UK.

Amiblu GRP pipes replace wooden penstock

After 23 years, the wooden penstock at the hydropower plant Auwehr in Austrian Mürzzuschlag was decommissioned and replaced by Amiblu GRP pressure pipes.

Further sustainability milestone at Amiblu

Amiblu Pipes Spain becomes the first European factory of CO2 neutral GRP pipes.

GRP drainage pipes for infrastructure project in Senegal

Amiblu supplies 8000 meters of GRP drainage pipes for the Bus Rapid Transit (BRT) project in Senegal, which is funded by the World Bank.

65,000 m GRP Pipes for Sifón de Cardiel Irrigation Project

Amiblu Pipes Spain has been awarded the supply of 65 km of GRP pipes for the Sifón de Cardiel irrigation project in Aragón.