Recycling comes last

Environmental activist Annie Leonard said it best: “Recycling is what we do when we’re out of options to avoid, repair, or reuse the product.” In the reduce, repair, reuse, recycle mantra, recycling comes last.

If you want to reduce your environmental impact, make pipes that last for generations. There’s no need to recycle what never should have been produced in the first place.

No one under fifty has lived a year without an Earth Day and every company faces questions from skeptical customers who have a keen sense of what they consider environmentally acceptable:

- Will our products be worth the investment?

- Will our pipes harm the ecology of the area where they’ll be installed?

- What is the environmental footprint of Amiblu products?

- What role does sustainability play at Amiblu?

Honest answers ask for transparency. And that’s what we promise to give you.

What sustainability means to us

Talking about sustainability starts with taking a good look into the mirror. Is what you see future-proof? Does it stand up to current and upcoming challenges, and is it determined to tackle them?

The challenges we’re approaching and already facing in connection with climate change are manifold, and most of them have in some way to do with water. Water is not a matter of course, nor endlessly available. Less precipitation and higher temperatures lower groundwater tables. And heavy rains in combination with increasing urbanization, featuring more and more sealed surfaces, bring existing infrastructure to the limits of its capacity.

Each and every one of us needs water to survive. Therefore, it needs to be appropriately managed and valued, today and for the next generations, with the smallest possible environmental impact. And that‘s what we at Amiblu have made our mission:

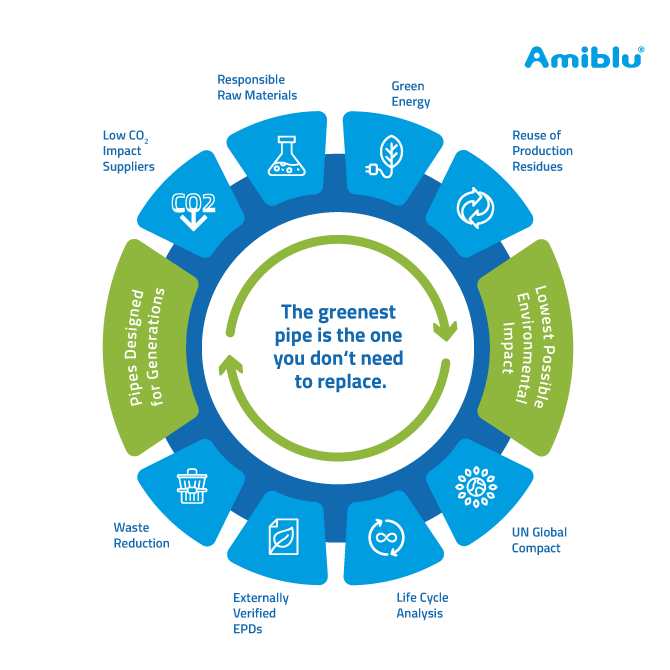

We reduce environmental impacts by making pipes that last for several generations.

LCAs for every single product

Cradle-to-gate studies show that 80-90 percent of GRP products’ environmental impact is determined at the design stage. A life-cycle assessment (LCA) is a powerful tool for learning which raw materials or manufacturing stages are the most critical for the environmental performance of the product.

We’ve set up the most comprehensive LCA (life-cycle assessment) platform in the pipe industry. This allows us to carefully evaluate and choose the most environmentally friendly raw materials, designs, and production processes for our products.

To date, we’ve compiled LCAs for over 1,200 products, which represent about 80% of our sales. We then condensed the big reports into easy-to-read, EU-standardized Environmental Product Declarations (EPD) and can, within hours, provide the data to stakeholders who want to learn more about the environmental impact of a specific product.

Using our LCA scenario generator, we can quickly compare the Carbon Footprint of various products from all Amiblu plants in a cradle-to-gate scenario. Furthermore, we can educate stakeholders on the impact of raw material selection and steer product choice towards greener and more responsible options.

We can also calculate the Environmental Cost of every project in monetary value and, thus, put a number on nature’s precious contribution.

Our dedicated team of environmental scientists works hand in hand with all departments and hierarchy levels, as we want the reduction of environmental effects to be part of the job of every single employee, especially when there’s a global water crisis.

LCAs are only a point of departure

Learn more about how GRP outperforms other materials and how Amiblu seeks to battle the world’s water crisis.

© Amiblu Holding GmbH, 2025